Description

Fields of application

- Failure diagnosis

- Detecting and localizing of sporadic errors

- Cycle time optimization

- Long-term recording of measured values

- System documentation, TPM/OEE, EU-Machinery directive

- Condition monitoring | Predictive maintenance

- Warranty: incorruptible clarification

- Quality assurance

- Installation, development, maintenance

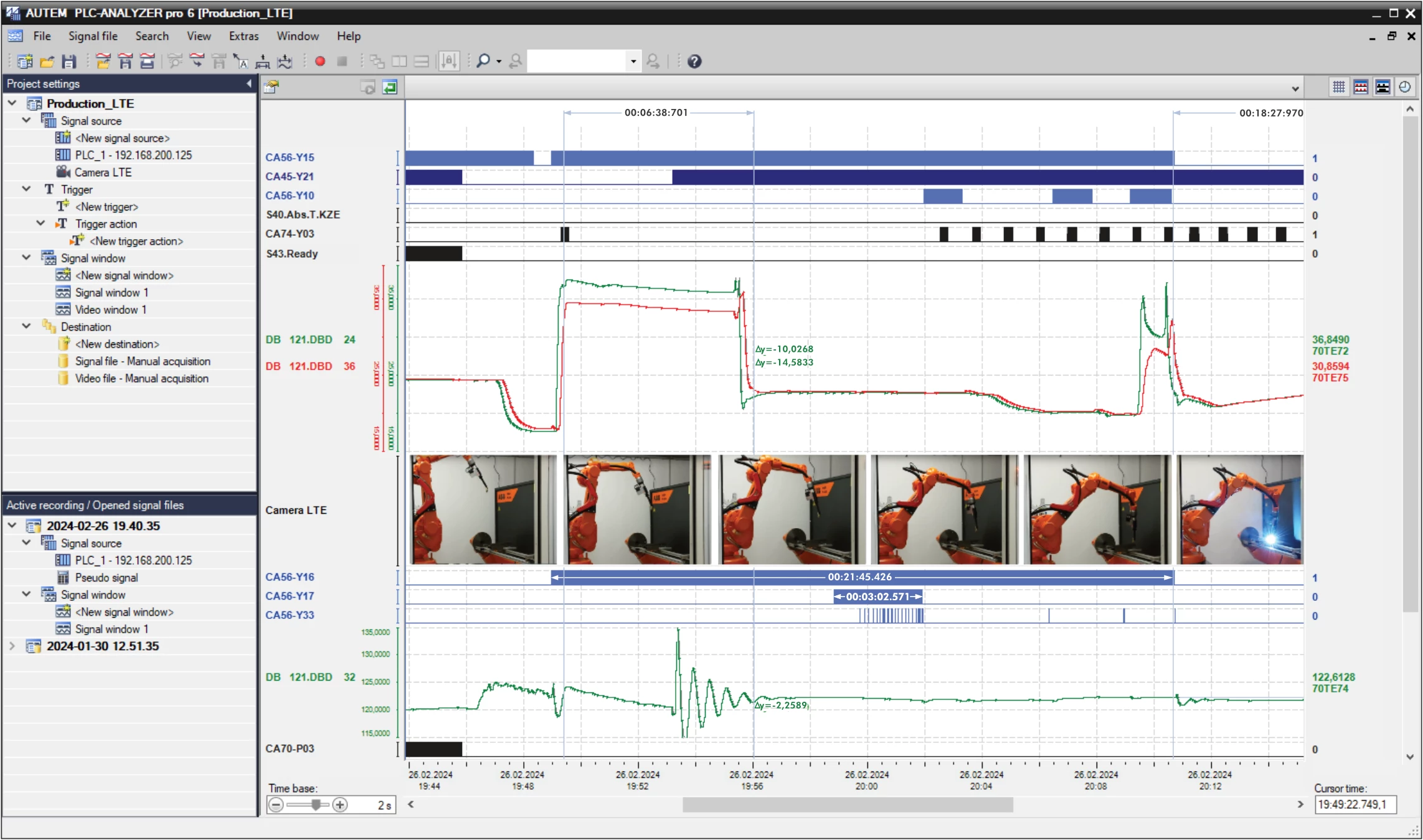

Live display allows the observation of the signal waveform in real time. Analysis and evaluation can already be carried out at the time of recording. In addition to long-term recording, trigger conditions can be specified for the acquisition of particular events. This allows rarely occurring sporadic errors to be specifically recorded for later analysis.

PLC-ANALYZER pro 6 has the decisive advantage of recording process data via standardized PLC interfaces. For example, for SIMATIC S7 signals can be acquired using TCP/IP PROFINET or MPI/PPI, PROFIBUS. All CODESYS communication paths, OPC-UA and many other PLC connections of various manufacturers are supported.

A programming device or notebook, that is connected for the purpose of programming the PLC, can be used for recoding process data without modification. By means of high-performance PLC drivers (in-house development) the PLC-ANALYZER pro 6 achieves sampling rates, which would not be possible with a OPC-UA-based solution.

The tiresome process of hooking up monitoring cables is now a thing of the past. Cycle-precise recording* is attractive because of the complete acquisition of measured values in each PLC cycle. Up to 16 million variables from 250 signal sources can be recorded simultaneously (theoretical values).

PLC-ANALYZER pro 6 simplifies the signal selection by using symbol files or projects of the PLC programming software. Loading e.g. a TIA / STEP7 project makes all settings and variables immediately available. Symbols can also be imported directly from the TIA PLC.